While the transparent human being is a nightmare vision for every dedicated data protectionist, the transparent machine is a consistently desirable goal for service providers. Under the keyword “Service 4.0”, a new project is currently underway at one of Innosoft’s customers, in which the system, which up to now mainly consists of Resource Planning and Field Service Management, is to be further expanded and equipped for future requirements.

As with “Industry 4.0”, the idea of “Service 4.0” also requires changes in the customer service processes and a stronger integration of digital technologies for the direct connection with the customers. The new web solutions of the Dortmund software house Innosoft play a major role in this. Above all, the new Customer Portal offers great opportunities to efficiently exploit the potential opened up by the developments of “Industry 4.0”, for example through predictive maintenance and early detection of problems in order to avoid impending production interruptions and to extend the service life of the systems – thinking of e.g. “machine learning”.

In order to further advance the digitalization of processes in the sense of Industry 4.0, Innosoft helps together with other partners to connect machines and plants even more closely and in detail and to integrate them into the existing IT environment. When setting up the Customer Portal, the internal and external Ticket System enables ticket recording around the clock and helps decisively with the digitalization of all service processes.

Via the access portal, the customer has a clear view of the constantly updated machine file including all previous and upcoming service activities at all times and can also create tickets independently in the external system. In addition, when the machine is directly connected to the system, preventive measures can be planned more specifically and service tickets can even be triggered automatically by means of defined machine messages.

The added value is obvious

The great added value that machine manufacturers can offer their customers with the Customer Portal is obvious: a significantly more intensive relationship through even greater proximity and transparency in the support of the machines they have purchased or rented from them. And so companies that can already access their product data via such an external Ticket System are predominantly enthusiastic about this direct contact with the supplier of their machines.

In order to get a clear picture of the possibilities of the customer portal, an easily comprehensible thought game from everyday private life can help: If, for example, an automobile manufacturer were to give its customers access to all data on the vehicles they have purchased from him, car owners would not only be able to view all maintenance and repairs and trace all installed parts and optional equipment.

They could also call up data such as mileage for specific periods of time and — using the appropriate software functions — create evaluations and run simulations and preventive measures. Even if the vehicles were repaired or maintained in another workshop and foreign parts were installed, the customers could report this and thus ensure complete documentation. As a car owner, you would always have an overview of the current status and could plan ahead.

The imaginary scenario becomes reality

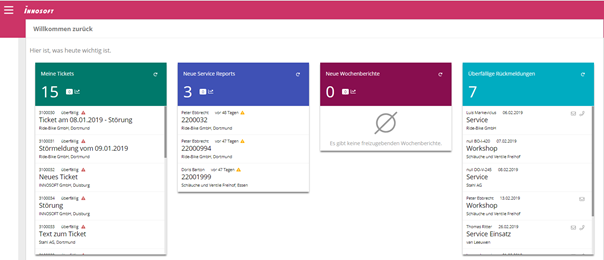

In the Customer Portal of Innosoft the subjunctive becomes reality. After the login, the customer can access various functions in the portal. Besides the display of past and planned service calls, the customer has a comprehensive view of his machines, whose data Innosoft has taken over from the connected ERP system, including the purchased spare parts that have been installed during the machine’s life. And if the machine itself is connected to the system, tickets can be generated automatically via a directly addressed web service, for example when a measured value reaches a critical value.

Rights profiles for users

An authorization concept tailored to the requirements regulates in detail which user with which rights profile may view and/or edit which data of certain machines. In order to query only the most necessary data by the external users, the input masks can be configured separately. For example, the external one can contain significantly less data than the internal ticket system. If required, a document management system can also be connected. It also makes sense to connect it to quality management software to which complaints are transferred and which can also help to identify defective parts more easily and sort them out in time.

The Customer Portal as well as the other web solutions of Innosoft are provided in the current project as a cloud application, but hosting in the company’s own IT infrastructure is of course also possible easily. The data in the cloud is synchronized via replications with the central Innosoft database at the customer’s premises. In doing so, the scope of the data is limited so that the complete data stock does not have to be accessed.

Quick access to the machine file

The end customer always has quick and easy access to the machine file and ticket overview in the Dashboard and the Customer Cockpit. The reactions to the new Customer Portal, that have been experienced so far, have been consistently positive, and acceptance is high on both sides of the machine. And even though glass as a material will probably never be the main component in machine and plant construction, the future promises service personnel an almost complete picture of the machines.