Clearly coordinated technical and organizational measures ensure stable and transparent processes. Structured maintenance plays a key role in keeping systems, equipment, and buildings functional in the long term. It plays a central role in field service management (FSM), as assignments, resources, and appointments must be precisely coordinated. Digital resource planning allows processes to be controlled efficiently, information to be recorded centrally, and ongoing measures to be tracked transparently.

Definition: What is maintenance?

In many service organizations, reliable planning of maintenance and service calls forms the basis for stable processes and satisfied customers. The term maintenance describes all measures taken to maintain or restore the operational readiness of technical systems and devices. In the context of FSM, it encompasses the coordination, scheduling, and documentation of all activities that ensure orderly and safe system operation. Structured planning creates transparency, defines clear responsibilities, and enables the efficient use of personnel and resources.

Maintenance objectives and tasks – the basis for efficient service processes

Well-planned organization of maintenance processes plays a key role in keeping technical systems and equipment functioning properly in the long term. The focus here is on clear objectives and specific tasks in order to design efficient processes and make optimal use of resources:

Efficient maintenance planning for transparent processes

Coordinate maintenance and service assignments clearly, manage resources in a targeted manner, and keep a reliable eye on deadlines. With Innosoft, you can organize your maintenance planning digitally, in a structured and flexible way.

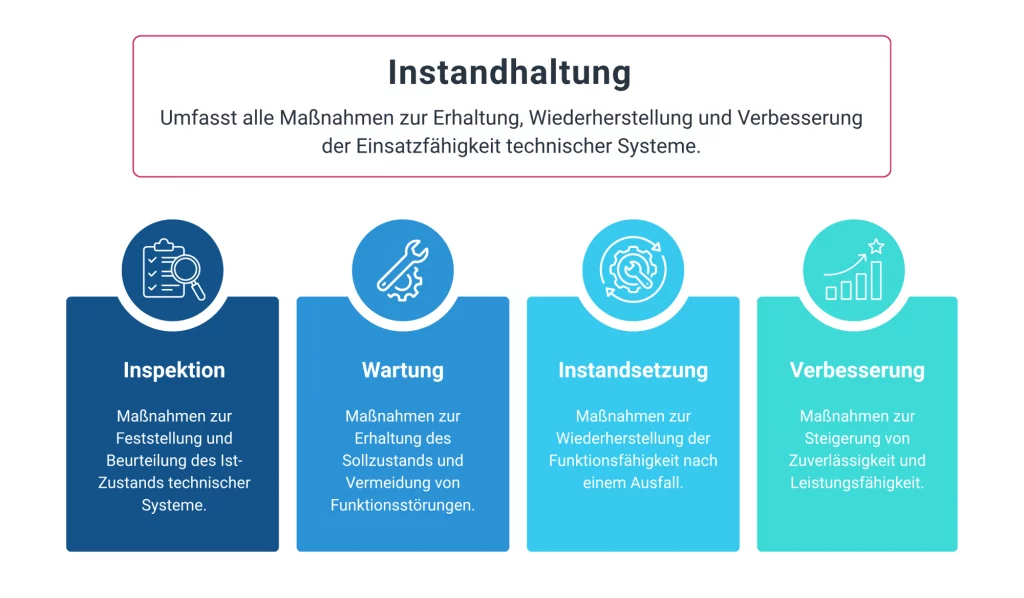

Maintenance: four measures for long-term operational reliability

Effective maintenance management includes measures aimed at maintaining the condition of technical systems in the long term. Each of these measures fulfills its own task and contributes to making operational processes predictable and reliable. A structured approach allows maintenance and service tasks to be coordinated in a targeted manner and their results to be documented in a traceable way. The following four basic measures form the basis of a systematic approach in FSM:

Types of maintenance strategies – the basis for targeted resource planning

Depending on the area of application and technical requirements, different maintenance strategies are used in FSM. They determine when and how maintenance measures are carried out and what priorities apply to planning and resource allocation. Each strategy pursues the goal of organizing service calls efficiently, reducing downtime, and managing costs transparently. Choosing the right approach has a significant impact on how smoothly the processes between dispatch, technicians, and customers run.

Reactive maintenance – intervention after a fault has occurred

In reactive maintenance, service calls are only planned once a malfunction or failure has already occurred. This strategy focuses on fast response times and the rapid restoration of operational capability for the affected systems. In FSM, it is often used in areas where short-term interventions make more economic sense than regular maintenance routines.

Typical characteristics:

- Service calls after failure or fault report

- Flexible resource planning through short-term scheduling

- Low planning and monitoring costs

- Increased workload for service teams in the event of frequent faults

- Higher follow-up costs due to unforeseen downtime

Preventive maintenance – prevention instead of reaction

Preventive maintenance aims to avoid breakdowns through regular servicing. In FSM, maintenance dates and service intervals are planned in advance. With the help of preventive maintenance, resources can be used in a targeted manner, workloads can be distributed evenly, and unplanned downtime can be prevented. This strategy is particularly suitable for customer systems where high availability is crucial.

Typical features:

- Scheduled maintenance at fixed intervals or according to usage units

- Long-term resource planning for service teams

- Increased system availability and process reliability

- Predictable resource utilization in FSM

- Greater organizational effort for schedule management and coordination

Condition-based maintenance – decisions based on current system data

In condition-based maintenance, service calls are planned based on actual condition data. Sensors and digital monitoring systems provide real-time information on performance, temperature, or wear. The FSM system uses this data to automatically schedule maintenance calls as needed. This avoids unnecessary routine assignments and allows resources to be used in a targeted manner.

Typical features:

- Data-based assignment planning based on measured conditions

- Maintenance only when actually needed

- Use of IoT and monitoring systems

- Reduced effort for recurring maintenance

- More efficient coordination in FSM through real-time information

Predictive maintenance – forward-looking planning through intelligent analysis

Predictive maintenance is the most advanced strategy and uses AI-supported analysis and historical data to identify potential failures in advance. In field service management, this approach enables precise resource planning, with maintenance orders being generated automatically before a failure occurs. This minimizes downtime and ensures that technicians are deployed when needed.

Typical features:

- Forecast-based planning of maintenance assignments

- Use of sensor data, AI, and predictive analytics tools

- Prevention of unplanned failures through early detection

- High level of data integration between systems and service processes

- Maximum efficiency in FSM through forward-looking resource management

Digitally map maintenance planning and manage it efficiently

Use centralized data, automated processes, and mobile feedback to coordinate service calls in a targeted manner. With Innosoft, you can create clarity about appointments, resources, and responsibilities.

Structured maintenance planning with modern tools

Proactive organization of maintenance processes requires an overview of systems, deadlines, and available resources. Digital systems facilitate the coordination of maintenance and service calls, reduce administrative effort, and ensure the traceability of all measures.

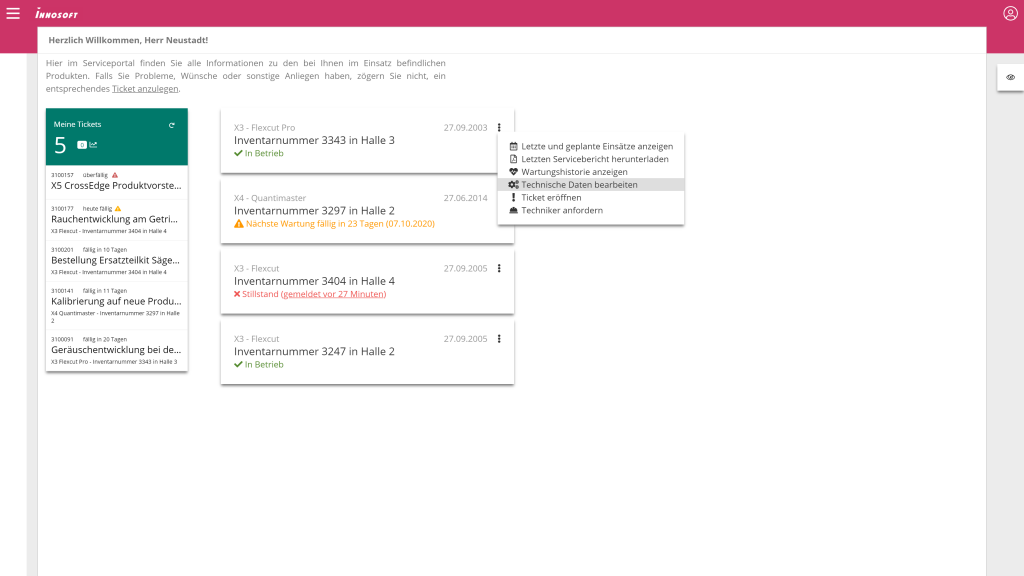

In FSM, specialized software creates the basis for structured, efficient, and data-driven maintenance. FSM software such as Innosoft provides targeted functions for this purpose, enabling maintenance processes to be planned, coordinated, and mapped transparently and efficiently:

Digital maintenance planning – keep track of all assignments with Innosoft

Proactive maintenance planning requires systems that centrally bundle information and transparently map processes. In field service management, Innosoft provides the basis for clearly planning maintenance and service assignments, flexibly controlling them, and adapting them to current requirements at any time.

Appointments, resources, and responsibilities can be coordinated with the support of the system, enabling maintenance measures to be prepared efficiently and documented in a traceable manner. The result is a clear structure that both reduces administrative effort and improves service quality.

Interested in efficient maintenance planning with Innosoft?

We would be happy to show you how you can digitally optimize your service processes and manage your assignments more precisely.

FAQ – Maintenance in field service management

In field service management, maintenance encompasses all organizational and technical measures that contribute to the efficient planning of service calls and ensure the operational readiness of plants, devices, or systems. This includes the planning, scheduling, execution, and documentation of maintenance and service orders in the field.

The key components include planning, coordination, execution, and tracking of service calls. The focus is on operational reliability, availability, and transparency of processes. Structured processes and the use of digital tools enable service teams to work more efficiently and process customer inquiries more quickly.

Maintenance in FSM is divided into four basic measures:

- Maintenance – preventive measures to maintain the target condition.

- Inspection – checking and evaluating the actual condition.

- Repair – restoring functionality after a failure.

- Improvement – targeted measures to increase reliability and service quality.

Depending on the situation, reactive, preventive, condition-based, or predictive strategies are used in FSM. They differ in terms of whether maintenance measures are planned after a failure, at regular intervals, based on measured values, or through data analysis. The choice depends on the scope of service, plant criticality, and customer requirements.

In reactive maintenance, service is only performed when a malfunction or failure is reported. This strategy is particularly suitable in FSM for less critical systems or short-term malfunction calls, where fast response times are more important than scheduled maintenance.

Preventive maintenance serves to prevent breakdowns through regular maintenance work. In FSM, maintenance intervals are defined, service teams are scheduled in advance, and tasks are systematically documented. This keeps customer systems operational for longer and makes service work easier to plan.

Predictive maintenance uses sensor data and digital analytics to identify potential malfunctions in advance. In FSM, this strategy enables data-driven resource planning, whereby technicians are automatically deployed when there is an actual need for maintenance.

Maintenance is one aspect of servicing. While servicing encompasses all organizational, technical, and administrative tasks, maintenance in FSM focuses on regular service calls that ensure the proper condition of customer systems.

Maintenance describes the entire process of planning, controlling, and monitoring service calls. Repair, on the other hand, refers specifically to measures taken after a breakdown, i.e., restoring the functionality of a system or device.

Structured maintenance ensures transparency, planning reliability, and consistent utilization of service teams in FSM. It reduces downtime, increases customer satisfaction, and helps to reliably fulfill service contracts. Digital processes also create traceability and increase service quality.

Depending on the situation, reactive, preventive, condition-based, or predictive strategies are used in FSM. They differ in terms of whether maintenance measures are planned after a failure, at regular intervals, based on measured values, or through data analysis. The choice depends on the scope of service, plant criticality, and customer requirements.

Effectiveness is increased through digital resource planning, centralized data collection, and automated processes. FSM software such as Innosoft helps to manage maintenance orders, schedule technicians, and record service reports in real time. This allows resources to be used optimally and maintenance measures to be controlled precisely.